Food waste

We are committed to halving our food waste by 2030 from the 2019 baseline. Our intermediate target is to achieve a 25% reduction in food waste by the end of 2025.

By the end of 2024, the relative food waste generated at K-food stores had decreased by 21% from the 2019 baseline.

Our primary means of preventing food waste include selection management at K-food stores and Kespro’s cash-and-carry outlets, as well as forecasting and material requirements planning. In practice, this means having the right amount of products that customers want in the right place at the right time. The most important decisions in terms of waste prevention are made at the selection management stage.

As a product’s ‘best before’ or ‘use by’ date approaches, K-food stores can sell the product at a discount. The majority of customers at K-food stores purchase products with red labels that are at risk of becoming waste. The popularity of these red-labeled products is also reflected in sales data. In 2024, nearly 50 million red-labeled products were sold in K-food stores (6 percent more than the previous year), with the highest quantities being bread, ready meals, and meat.

To reduce waste, stores have also developed their own innovative food waste products from brown bananas, for example.

K-food stores donate edible food products they can no longer sell to local charities, which then distribute the products as food aid to those in need.

Our consistent measures have been particularly successful in reducing the amount of food ending up as waste at stores. In 2024, the amount of inedible food waste from K-food stores that ended up as waste decreased by 2% from the previous year.

At times, waste is generated in the warehousing operations of fruit and vegetables. Fruit and vegetable products may be damaged on their way to the warehouse, and some of them fail to meet the required standards because of their appearance. These kinds of edible yet non-sellable fruit and vegetable products are excellent ingredients for soups, for example.

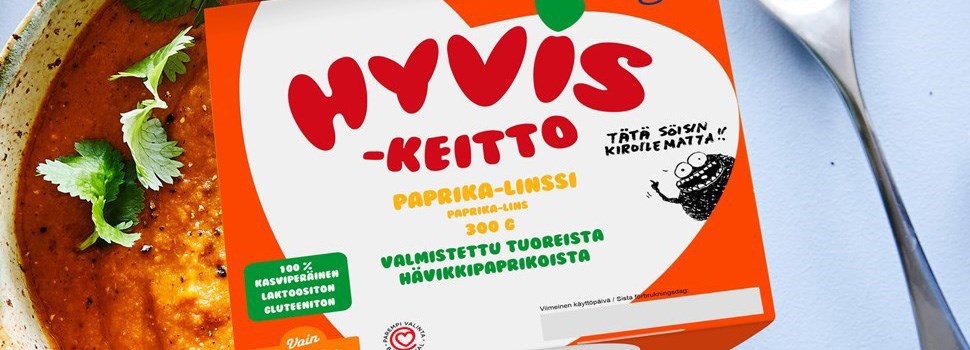

In 2023, the vegan Hyvis sweet pepper and lentil soup was launched alongside the Hyvis tomato and cheese soup. The ingredients of the Hyvis sweet pepper and lentil soup include waste sweet peppers from Kesko’s central warehouse. In November 2023, the soup was selected as the winner of the Food and Beverage category in the Most Sustainable Product in Finland competition.

In 2023, more than 17,000 kg of waste fruit and vegetables was utilised in our own circular economy products.

At Kespro's cash-and-carry outlets, some of the key measures to reduce food waste are data-driven sales prediction and discount shelves for products being removed from the selection or nearing their expiry date. Systematic monitoring of waste data, monthly highlighting of successes and active communication related to waste have also been identified as effective ways to minimise waste.

In 2024, the food waste percentage – or the share of kgs that end up as food waste – was 1.4% at Kespro’s 13 cash-and-carry outlets. In 2024, the lowest figure was reached at Vaasa and Tampere outlets with a waste percentage of 0.8%. Around 40% of all the food waste recorded by the cash-and-carry outlets is donated to food aid, which means the proportion of food waste that actually ends up being disposed of is only around 0.8%.

In 2024, Kalatukku E. Eriksson, part of Kespro Erikoistukku, began food donations, through which approximately 30% of fish products that were expiring or otherwise destined for waste were redirected to food aid and subsequently used as raw materials in waste food restaurants.

In addition to outlets, Kespro helps its customers to reduce food waste by sharing expert knowledge and exchanging ideas with customers. The foodservice sector accounts for around 17% of all food waste in Finland. Almost 60% of foodservice waste is service waste such as food left over from buffets. Wastage can be reduced by streamlining kitchen processes at the preparation stage and by using appropriate tableware and presentation in buffets, for example.

In cooperation with Gasum, we use inedible food waste to produce biogas, which is used as energy in the production of new Pirkka products such as ice creams and Karelian pasties. The operating model involves two manufacturers of Pirkka products, hundreds of K-food stores, Kespro’s cash-and-carry outlets and the Kesko Logistics central warehouse.